Compression springs are the most widely used parts in industrial applications. Supported by the upper and lower ends, the coils in between are action coils which thrust or stretch with repetitive motions up and down.

Configuration of Compression Springs:

-

Materials: piano wires, stainless steel wires, high carbon steel spring wires, nickel wires, phosphor bronze wires, bronze wires, and beryllium copper wires.

-

Wire diameter: ø0.06 mm ~ ø3.5 mm.

-

Spring O.D.: ø0.35 mm or more.

-

Total number of coils: number of active coils plus the coils forming the ends.

-

Effective coils: number of action coils.

-

Free length: the length of an unloaded spring in a free state.

-

Load capacity: our technical staff will provide assistance to customers with the design.

-

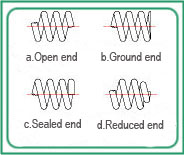

End shapes: as the figure shown (left), as per your specific need.

-

Surface treatment: plating, anti-rust oil, skimming, as per your specific need.

A proper specification design helps create a good spring durable and resistant to fatigue. We provide assistance to our customers from designs, samples, production and shipping. We are always serious in production and thoughtful in services. (Call us at: 02 -22868885)

|

|